A new Inner Tracking System (ITS) with a new high resolution, low-material-budget silicon tracker based on CMOS monolithic active pixel sensor (MAPS) technology is being installed in the ALICE cavern. In the MAPS technology, both the sensor for charge collection and the readout circuit for digitization are hosted in the same piece of silicon instead of being bump-bonded together. The chip developed by ALICE is called ALPIDE, which uses a 180nm CMOS process provided by Towerjazz. With this chip, the silicon material budget per layer is reduced by a factor of seven compared to the present ITS. The ALPIDE chip is 15x30 mm2 in size containing more than half a million pixels organized in 1024 columns and 512 rows. Its low power consumption (<40 mW/cm2) and excellent spatial resolution (~5 micrometer) are perfect for the inner tracker of ALICE.

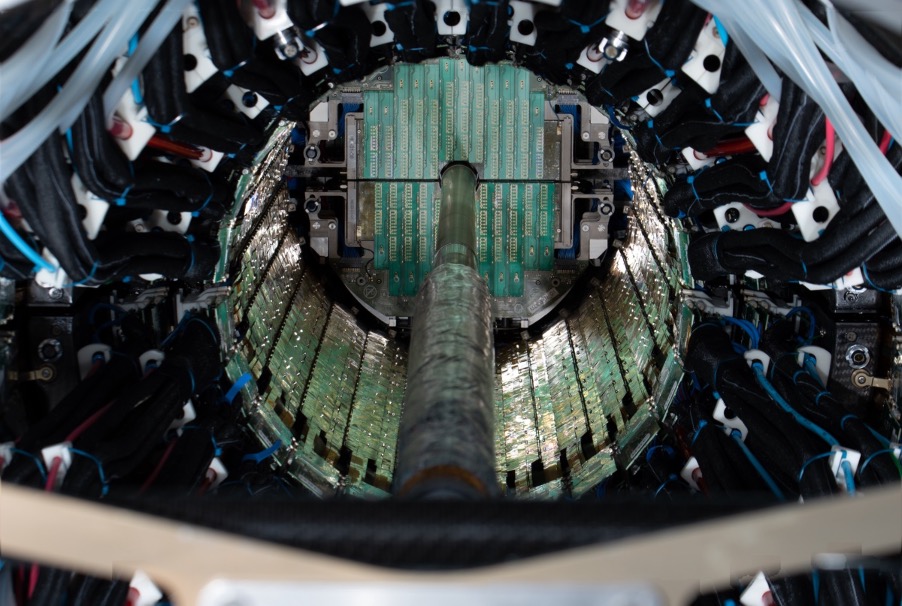

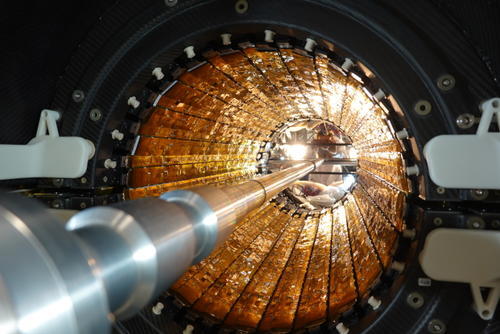

The ITS consists of seven cylindrical layers of ALPIDE chips summing up to a total area of 10 m2 and 12.5 billion pixels. The pixel chips are installed on staves with radial distances from 22 mm to 400 mm to the interaction point (IP). The beam pipe is also newly designed with a smaller outer radius of 19 mm, allowing the first detection layer to be placed close to the IP at a radius of 22.4 mm.

ITS Outer barrel was installed in March 2021.

ALICE ITS Outer Barrel installation photos in CDS:

- https://cds.cern.ch/record/2756341

- https://cds.cern.ch/record/2758788?ln=en

- https://cds.cern.ch/record/2759554?ln=en

Installation Videos:

Here is a chronological story of the ITS Outer Barrel (OB) installation:

1. ITS Outer Barrel Bottom (ITS OB BOT) left CERN Bat 167 on 16 March at 4am:

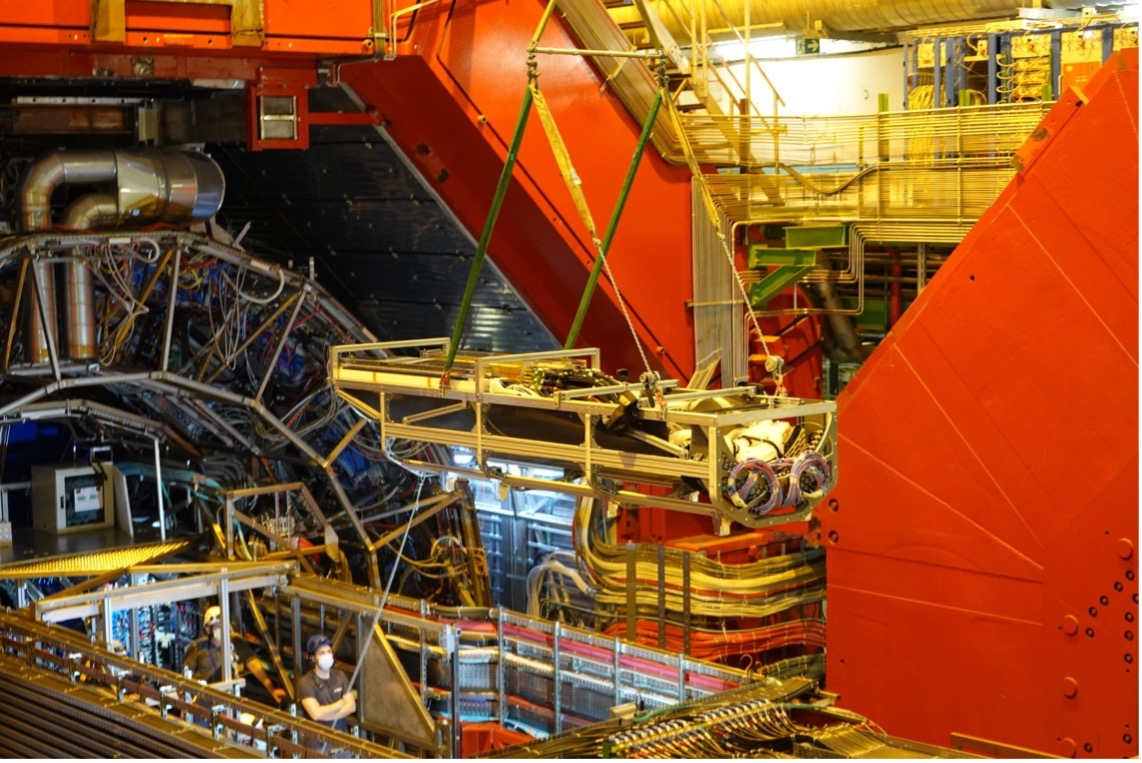

2. ITS OB BOT was lifted from the truck at 8am

3. and lowered in the ALICE pit and safely landed on the low-beta platform.

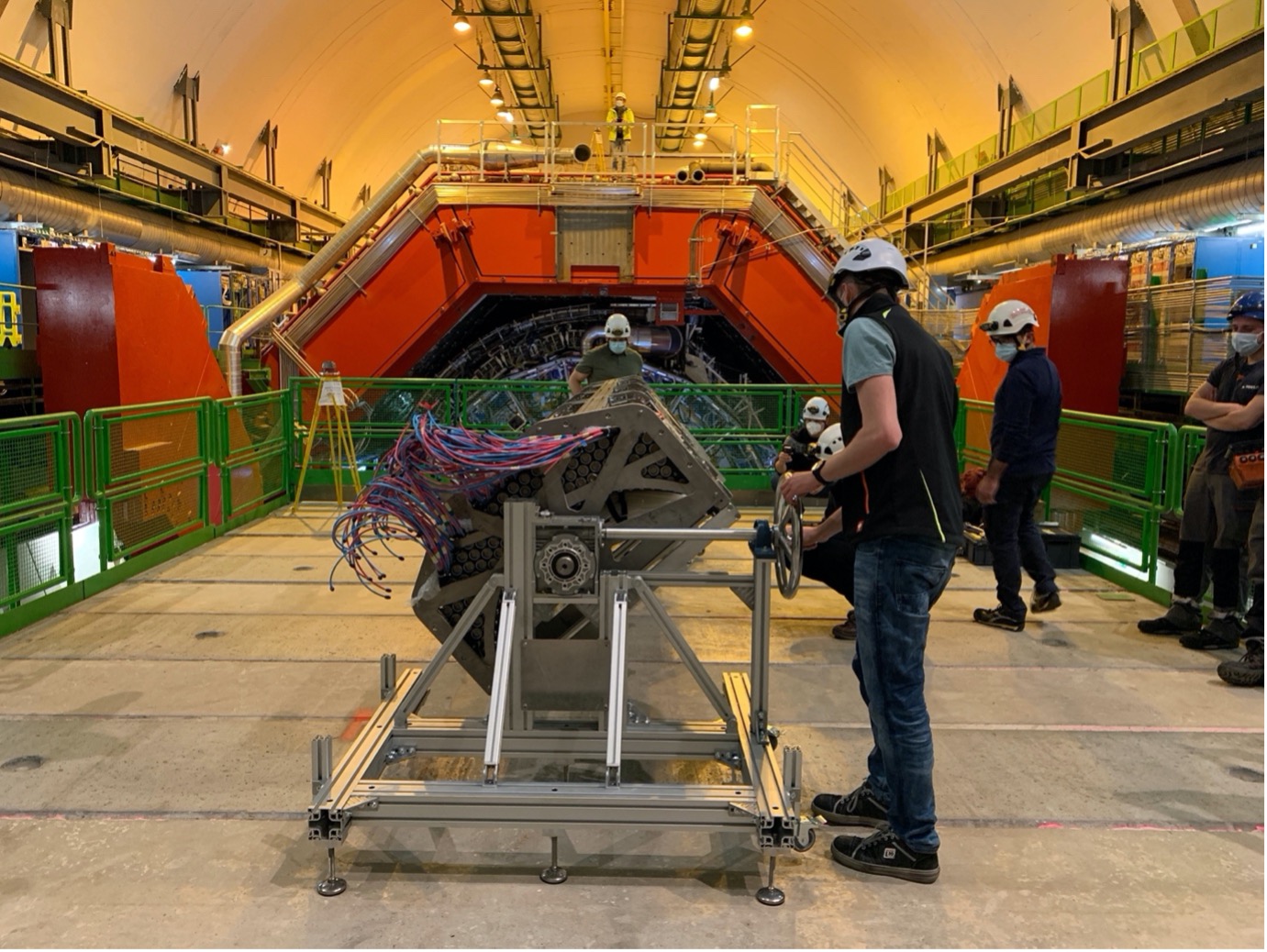

4. once there the mechanics team disconnected it from the wheeled suspension frame. The ITS OB BOT, still attached to the aluminium support structure, was moved towards the Miniframe.

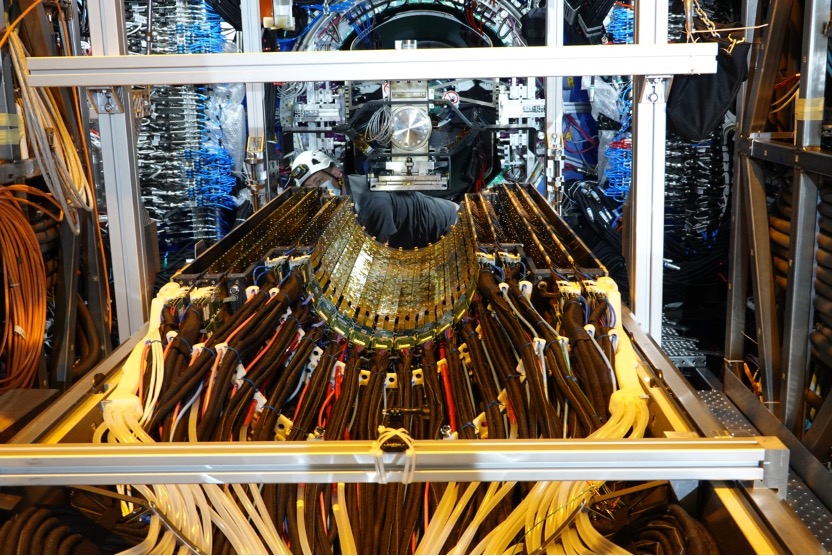

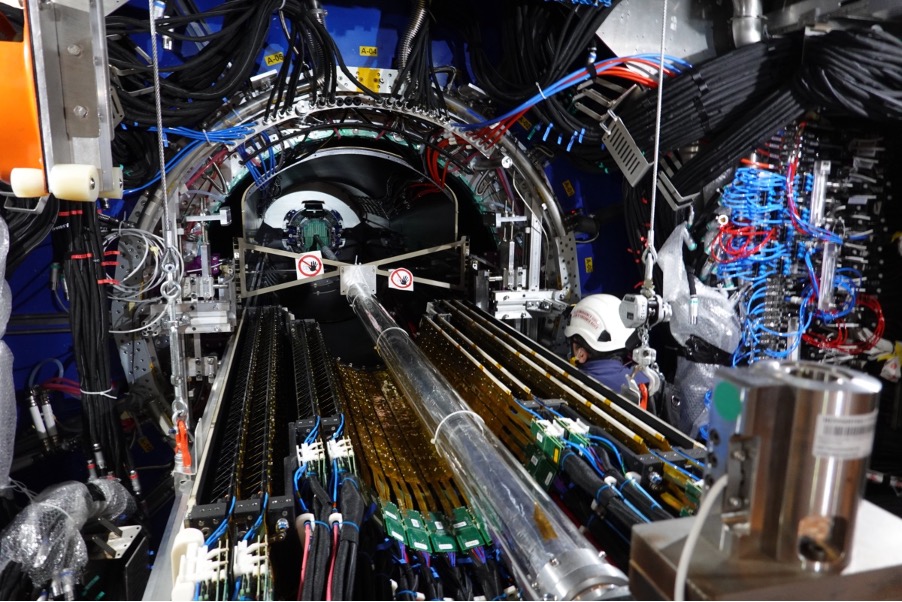

5. On the mini-frame the ITS OB BOT was prepared for installation. The plexiglass covers protecting the staves were removed. The detector was attached to the cage rails to guide it inside the TPC

7. ITS OB BOT inside TPC: the bottom half barrel was pushed slowly towards the MFT till it reached the final position. Then a metrological survey was performed, prior to the installation of the TOP Half Barrel

8. ITS OB TOP was moved from 167 to P2 on 18 March. ITS OB TOP rotation:

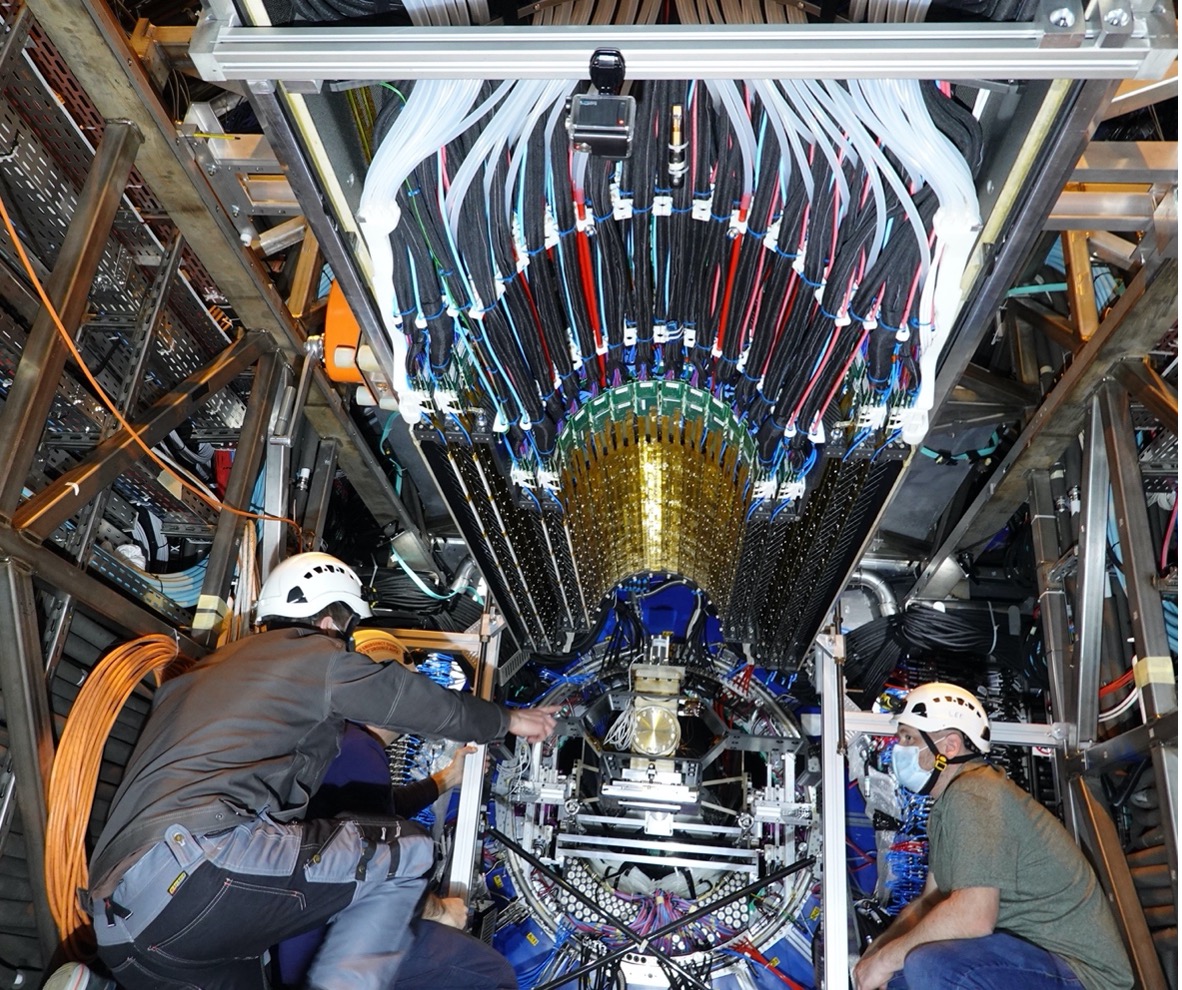

9. ITS OB TOP insertion:

10. ITS OB TOP reached its final position: